A new era of glass: a scientific and technological extravaganza at the Düsseldorf trade fair

Release time:

2024-10-29 00:00

Source:

1970: The exhibition of the glass industry in Düsseldorf, Germany, is unveiled, with an impressive number of innovative products and strengthened cooperation between the global glass industry. After decades of development, Glasstec has become one of the world's largest international glass exhibitions.

From October 22 to October 25, 2024, more than 1,250 exhibitors and 40,150 trade visitors from 52 countries gathered in Düsseldorf, Germany. The range of exhibits covers all aspects of the glass industry, including glass products, glass manufacturing machinery and equipment, architectural glass, automotive glass, optical glass, glass fiber, etc.

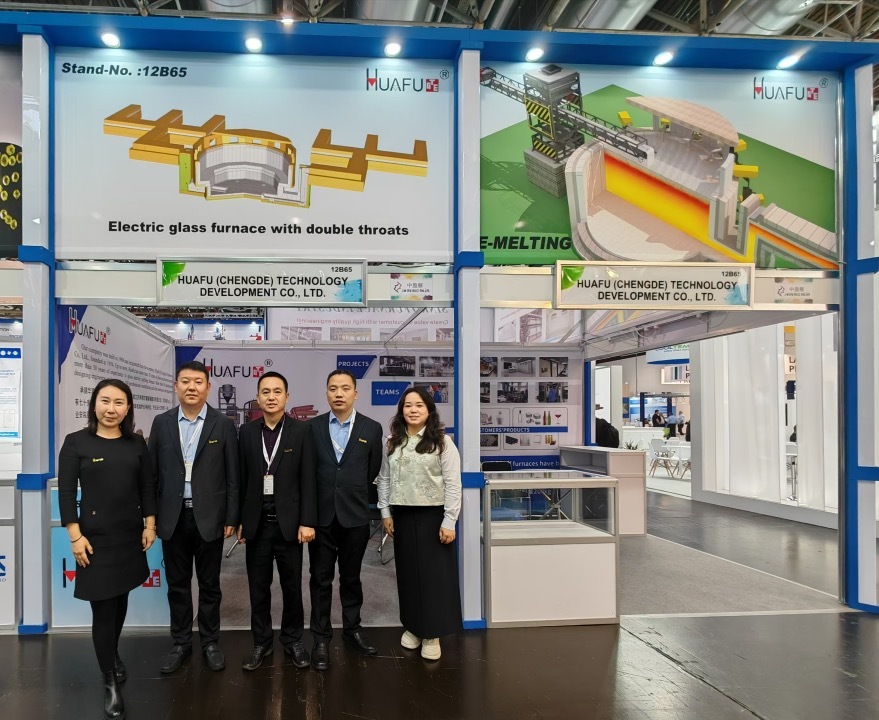

Glasstec points the way for the future development of the glass industry and stimulates new vitality in the market. Chengde Huafu Technology Development Co., Ltd. and a group of five people participated in this international exhibition, and the glass electric melting furnace won the favor of many visitors with its unique performance and environmental protection concept. Customers from the United States, Algeria, Egypt and other countries have expressed strong cooperation intentions for our products, and have received more than 20 groups of customers. Through these negotiations, we also understand the new dynamics of the international market and customer needs, which has laid a solid foundation for us to expand the international market and enhance our brand influence.

Looking forward to the future, we will continue to uphold the corporate philosophy of "providing customers with perfect and reliable solutions", continue to innovate technology, and provide more professional and thoughtful services to customers around the world. At the same time, we will also actively participate in various exhibitions and activities at home and abroad, constantly broaden our horizons, improve ourselves, and make unremitting efforts to achieve the company's long-term development goals.

Related News

Chemical reaction in a glass electric melting furnace

As our main machine products for glass processing, the glass electric melting furnace has a pivotal position, so we want to tell you about the relevant knowledge of this glass electric melting furnace today, I hope you can read it carefully.

The degree of high temperature resistance of the glass electric melting furnace

The glass processing industry is an unpopular industry in China, and there are few people engaged in it, but our annual demand for glass is indeed the first in the world, and such a large demand-supply ratio has not led to a large number of practitioners to change careers, what is the reason for this? I think maybe I don't know much about professional glass electric melting furnace technology. Many people have never been involved in this field, and they don't know much about its technology, so this is the main factor in the current lack of talent in the glass industry.

What are the advantages of borosilicate glass and how it differs from ordinary glass

High borosilicate glass is a special glass material with low expansion rate, high temperature resistance, high hardness, high light transmittance and high chemical stability. Due to its excellent performance, it is widely used in solar energy, chemical and pharmaceutical packaging, electric light sources, craft jewelry and other industries. Its good performance has been widely recognized by all walks of life in the world, especially in the field of solar energy, its application is becoming more and more extensive, and developed regions such as Germany and the United States have also been more widely promoted. The high borosilicate glass fire resistance and physical strength make it ideal for laboratories. It is used in the manufacture of high-durability glass in laboratory equipment, such as beakers and test tubes. Glass cookware is another common usage. The U.S. standard plate is almost entirely made of borosilicate glass. High borosilicate glass measuring cups with scales can be used for measurement and are also widely used in American kitchens. High-quality high borosilicate glass tube processing equipment, high transparency and wear resistance. Wear-resistant, smooth surface, easy to clean, healthy and hygienic. It can be used for solar collector tubes, chemical instruments, dayware and lighting glass. It is characterized by a small coefficient of expansion and is not easy to break under sudden temperature changes of 0-200 degrees; Resistant to acid and alkali, water, corrosion, etc.! High borosilicate glass, also known as hard glass, uses the properties of glass to conduct electricity at high temperatures. It is heated inside the glass to melt the glass.

The main cause of stones in the furnace of high borosilicate glass

There will be inclusions such as bubbles, nodules, crystals, and stones in the vitreous. These defects in the vitreous body greatly reduce the quality of the glass. In the case of borosilicate glass, stones are a dangerous defect in the vitreous. They are crystalline solid inclusions that appear in the glass and they have a great influence on the glass. They are more likely to be caused when borosilicate glass fiber precursors are stretched. Brushed guils and flying wires. Even if these stones do not cause breakage, they will greatly reduce the strength of the fiberglass.

Problem solving in the operation of automatic feeder

The solution of the belt conveyor frame colliding with the breast wall of the melting pool space of the electric melting furnace: add a collision power-off device at the head of the conveyor, and during operation, once the contact of this device touches the obstacle, the equipment will be stopped by the trigger switch.

Furnace pool wall air-cooled solution

In many electric furnace designs, the problem of pool wall air cooling is not considered, and only when needed is a fan is temporarily installed to pull a few pipes. In general, it will continue for the entire furnace age. There are two types of pool wall air cooling schemes: